Corintis empowers IC engineers with cutting-edge tools, IP, and hardware to drive the future of high-performance and sustainable computing. Revolutionizing IC design through the innovative co-design of logic and microfluidics, we seamlessly integrate custom cooling channels within IC dies for unparalleled cooling power, energy efficiency, and compact form factor.

Company profile

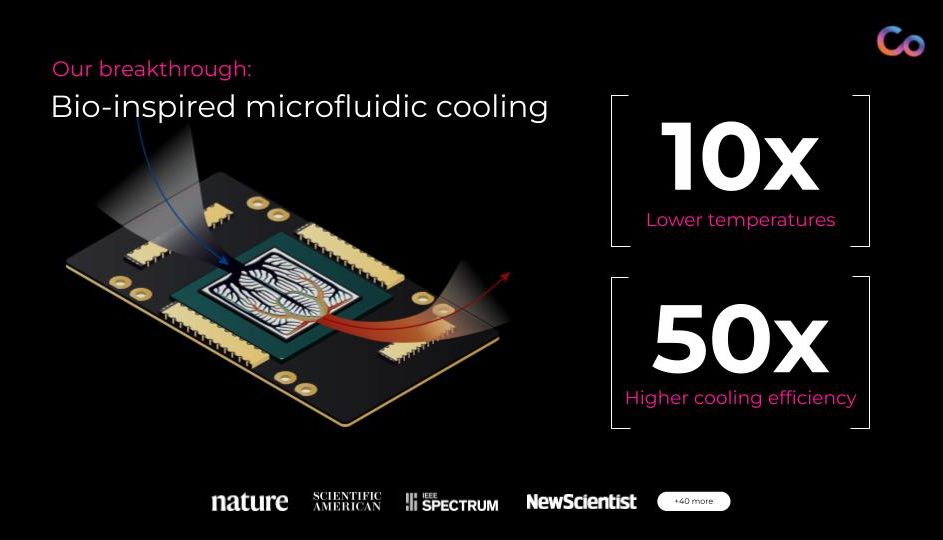

Corintis, an EPFL ecosystem spinoff, is revolutionizing the silicon industry by pioneering the integration of cooling and logic co-design. Drawing upon groundbreaking research from POWERLAB EPFL Switzerland, our technology delivers a 10x increase in heat extraction power and up to a 50x improvement in cooling energy efficiency. We equip chip engineers with the necessary tools, IP, and hardware to enable next-generation high-performance and sustainable computing, empowering them to embed custom cooling channels within IC dies. As a provider of IP, software, and hardware, Corintis collaborates with leading chip manufacturers, hyperscale data center operators, and data centers, offering our expertise and tools to facilitate the seamless incorporation of our disruptive technology into their existing manufacturing processes. Comprised of a diverse team of experts from various fields, Corintis is dedicated to pushing the boundaries of IC and related systems design and contributing to a more sustainable future for the industry.

- IC and microfluidic in-chip and on-chip cooling co-design software

- Microfluidic cold plates, packaging and CDU systems: design and manufacturing (custom and standard solutions)

- High density, compute power and energy efficiency, microfluidicaly cooled GPU/HPC servers and data center racks - manufacturing and retail.

Comprised of a diverse team of experts from various fields, Corintis is dedicated to pushing the boundaries of IC and related systems design and contributing to a more sustainable future for the industry.

Role in the project

In the All2GaN EU project, Corintis participates in Work Package (WP) Task 2.3.3, where they focus on addressing the challenges posed by the increasing demand for more efficient thermal management in GaN power devices and integrated chips. Leveraging their expertise in microfluidic cooling, Corintis plays a pivotal role in driving innovation and ensuring successful project outcomes. Working in synergy with EPFL POWERLab, Corintis contributes its proficiency in microfluidic cooling design, which allows for effective heat extraction in GaN devices and integrated chips. By incorporating these designs into silicon substrates, they facilitate a new era of high-performance heat sinks that can handle increased power densities while maintaining a compact form factor.

Additionally, Corintis provides valuable insights into the manufacturing process of cold plates and microfluidic packaging, helping to establish a scalable, cost-effective solution that can be adopted by the wider semiconductor industry. Their expertise in this area ensures that the cooling technology is both robust and reliable, paving the way for wider commercial use. Corintis also plays a crucial role in the dissemination of the project's findings, developing a user-friendly software tool that automates the cooling pattern design process. This tool enables industry professionals to readily incorporate Corintis' innovative cooling solutions into their workflows, resulting in more efficient and sustainable GaN power devices and integrated chips across the sector.

In summary, Corintis' active involvement in Task 2.3.3 is essential for pushing the boundaries of thermal management in GaN power devices and integrated

Key contribution

Corintis will be a key contributor to the All2GaN EU project, with a focus on optimizing and implementing advanced thermal management solutions for GaN power devices and integrated chips. Their primary areas of expertise will include:

- Topology-optimized design: Using their proprietary algorithms, Corintis will create optimized heat sink designs tailored to specific heat maps, significantly enhancing cooling performance.

- Manufacturing and integration: Corintis will produce silicon microfluidic cold plates and associated GaN device packaging, featuring the optimized cooling designs derived from power maps provided by EPFL.

- Reliability evaluation: To ensure the technology's viability for commercial adoption, Corintis will conduct a preliminary reliability assessment, focusing on potential challenges like clogging and thermal cycling.

- Software tool development: Corintis will develop a software tool to streamline and automate the cooling pattern design process, fostering wider industry adoption and promoting the distribution of European-created IP. By bringing their expertise to the project, Corintis aims to make a significant impact on the development of advanced thermal management solutions, contributing to the future of sustainable and high-performance computing.

Corintis SA

Building C, EPFL Innovation Park

Route Cantonale

1015 Lausanne

Switzerland

www.corintis.com