AlixLabs AB is a startup with a unique and cost-efficient nanofabrication technology for shrinking the dimensions of nanostructures to create next-generation nanoelectronics devices.

Company profile

Our innovative technology, which operates at the atomic level, enables us to reduce the number of process steps, resulting in increased throughput, cost savings, and lower CO2 emissions from exhaust process gases with high global warming potential (GWP). Our primary nanofabrication process, atomic layer pitch splitting (APS), utilizes selective plasma etching technology to etch semiconductor nanostructures sustainably. This breakthrough will produce advanced electronic components such as FinFETs and GAA-FETs without expensive processes. By replacing expensive nanofabrication processes with a single, cost-efficient step, the final product's price can be reduced, making it more affordable.

AlixLabs AB, is a startup spun off from Lund University founded in 2019 in Lund, Sweden. Our team primarily comprises individuals who have either graduated from or previously worked at Lund University. Our main office is in the Rise Pronano Facility in Lund, which includes our cleanroom. Also, we regularly utilize Lund University's cleanroom, where most of our research and development is conducted, and the company is in continuous collaboration with research groups from Lund University.

Our team primarily comprises individuals who have either graduated from or previously worked at Lund University.

Role in the project

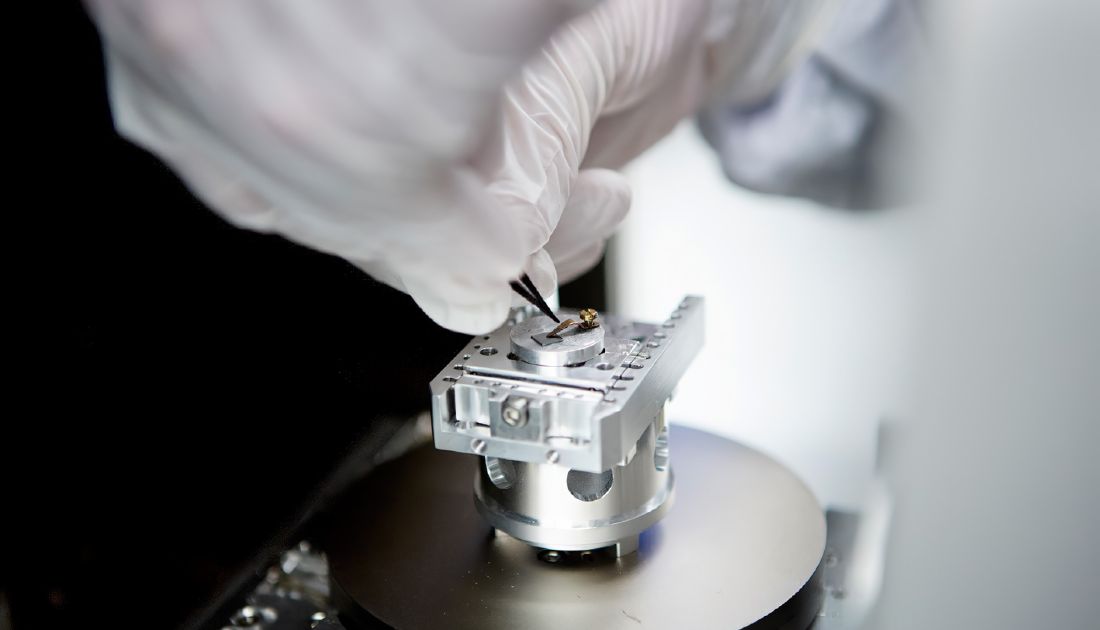

AlixLabs AB will develop an atomic layer etching (ALE) process for the etching of SiNx, GaN and other relevant materials in this project. As an advanced process in nanofabrication, ALE allows for the precise removal of material on an atomic scale and offers other advantages, such as surface smoothening and cleaning.

Key contribution

ALL2GaN project deals with insulator and semiconductor materials that need to be etched in a precise and controlled way on wafer sizes of 6″ and beyond. We will use our expertise to achieve a well-controlled etching of the materials with our own Oxford 100 ICP RIE tool or the etching machines in the cleanroom of Lund University, such as F-Apex ICP RIE and Cl-Apex ICP RIE tools by PlasmaTherm and then execute the process on the samples produced during the project in the WP1.

AlixLabs AB

c/o RISE Pronano,

Ole Römers Väg 1, Ingång H

223 63 Lund

Sweden

www.alixlabs.com